About

The brand deals in fuel cell power solutions that are cost-effective, carbon-efficient, virtually silent, and convert natural gas into electricity. The American company is known for its products that work smoothly with solar and storage to offer extended power backup and round-the-clock energy solutions for residential and commercial usage. The client approached us to move material from the inventory account to the WIP account, set specific approval limits for purchase orders, and create a demand forecast.

Project Highlights

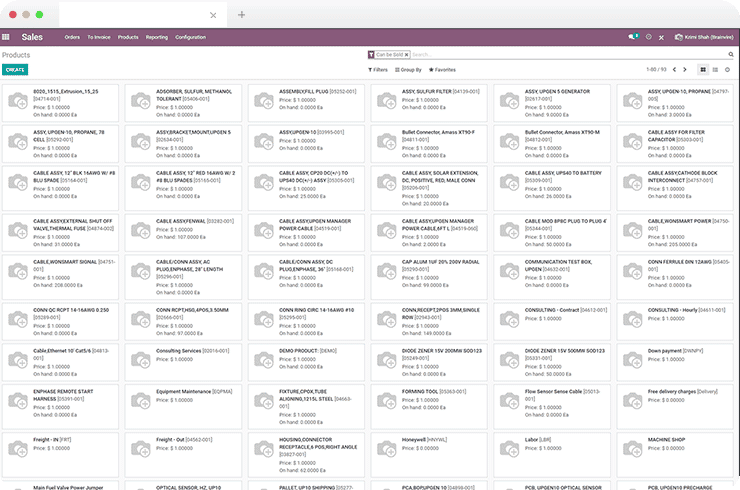

We provided several Retail Ecommerce Solutions to the client. First of all, we switched the client’s Odoo SaaS version 14 to Odoo.sh. It included creating an Odoo integrated material shortage report to ensure the availability of materials at all times. We integrated Solidworks with Odoo to simulate 3D designs for precision and save time in switching systems. Additionally, we created a centralized system that helped employees access all the designing data they needed for manufacturing. Finally, our team customized the WIP account to ensure smooth tracking of orders and created an approval mechanism with diverse rules.

The Challenges

- Non-Tracking of Required MaterialThe non-availability of the components required to create the bill of materials (BOM) was a challenge. It led to unnecessary delays in the manufacturing process.

- Manual Data FeedThe client had to refer to several systems and feed the data manually, making it time-consuming.

- Faulty Material Movement in the AccounThe material movement got tracked and moved out simultaneously in the Odoo default work in progress (WIP) account.

- Different Levels of ApprovalThe client wanted different levels of approval for processes, all having diverse conditions.

Tech Stack

Odoo

PostgreSQL

Azure cloud

DevOPS

Odoo.sh

Solidworks

Result

Streamlined Manufacturing Process

The central shortage report of materials helped the staff refill the short supplies well in time to carry out the manufacturing operations smoothly.All-in-One System

The central system significantly helped the employees to save time as they didn’t need to refer to different inputs to create a manufacturing order.Simplified Operations

The customized system automated the movement of orders, ensured better tracking, reduced errors, and simplified operations.A Well Defined Approval System

The client leveraged a well-developed approval system that ensured optimum utilization of the organizational resources and improved accountability.