About

The client's website's purpose is to develop and sell various industrial items. They provide a wide range of products in many different categories. In addition, the search function of an e-commerce website will allow customers to peruse inventory and make purchases. They connected with the Brainvire as a Odoo ERP Development team and as a result, all of their back-end operations are being taken care of by the various Odoo modules for handling things like Sales, Purchases, Inventory, and Manufacturing with .

Project Highlights

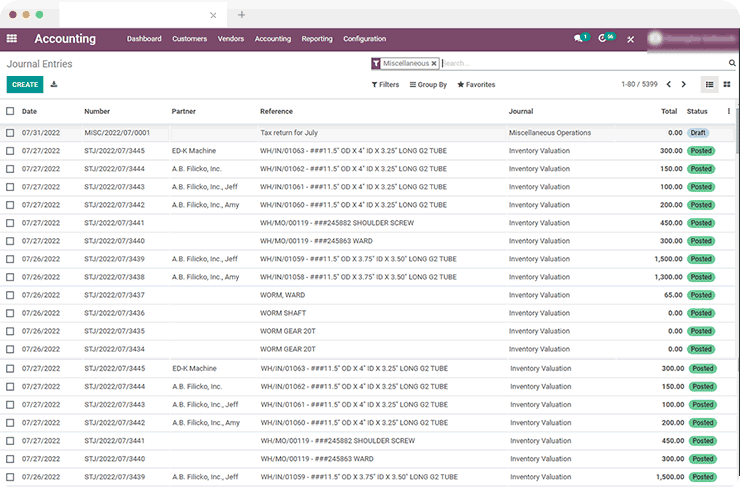

The client primarily deals with thermostat switches, designing and offering various types, such as bimetal snap action, fluid-filled capillary style, and digital style. The client reached out to Brainvire so that we could personalize their month-end inventory reports, stock valuation reports, cost of goods sold and consumed reports, purchase and manufacturing processes, vendor management, product transformation, and work center management for both internal and external locations.

The Challenges

- Proper Management:Plant management and Senasys communicate to manage accurate reports.

- Splitting Option:Options for splitting up a single-item manufacturing order.

- Administering Workcenters:Managing in-house and third-party work centers.

- Maximum Reuse Of Consumables:Maximum recycling of all consumables.

Tech Stack

Odoo

PostgreSQL

Odoo.sh

Azure DevOps

Result

Automatic Updates

The system will automatically assimilate data from the logs and fields to generate reports and fulfill production requests.Handle Multiple Purchases

Admins can easily manage various purchase orders and product journeys. Before moving on to the next operation, it became easy to see what a subcontractor vendor had done before.Transparent Process

Now the user can keep track of the changes made to the product. Also, this kept the system smooth and ensured that every user was accurate in their operations at each step of the manufacturing process.Easy Waste-Stock Management

Now, the client can put every scrap of material to good use; recycling and composting waste products have become much easier for end users.